DIN2391 Cold Drawn Precision Steel Tube Black Phosphated Welded Hydraulic Steel Tubes Description: DIN2391 Cold Drawn Precision Steel Tube Black Phosphated Welded Hydraulic Steel Tubes are meticulously crafted components designed for high-performance hydraulic systems. These tubes, known for their precision and durability, undergo a specialized cold drawing process to ensure exceptional strength and resilience. The black phosphated finish not only enhances corrosion

DIN2391 E355 Cold Drawn Seamless Precision Steel Tube Round Precision Steel Pipe Description: Our DIN2391 E355 cold drawn seamless precision steel tube round precision steel pipe is high-strength, precision- crafted product. Made from E355 steel, this round steel pipe features precise dimensions, tight tolerances and excellent mechanical properties. The cold drawing process ensures a smooth, consistent surface finish. Applications include hydraulic systems, fuel lines and

Large Diameter Hollow Steel Tube ERW Steel Pipe Welded Precision E355 E235 Steel Pipe Description: Specification: End Shape Beveled end, plain end, vanished, or adding plastic caps to protect the two ends as per customer's requirements Surface Treatment Oiled, Galvanized, Phosphate etc Technique Cold drawn & cold rolled Application 1. Automotive and mechanical pipes 2. Petroleum cracking pipes 3. High Pressure Boiler Pipe 4. Low and middle pressure fluid transportation

Light Weight Heat Exchanger Tube , Gr9 Gr12 Precision Seamless Titanium Tube Description Titanium tubes are the ninth most abundant element in the earth’s crust and the seventh most abundant metal. Its low density, slightly over half that of steel, and its high strength combination is the reason for the metals growing preference in both military and commercial aircraft. The alloying of titanium tubing with elements such as aluminum and vanadium increase the strength of

Gr12 Seamless Titanium Pipe ASTMB338 ASTMB861 Titanium Alloy Tube Main Date Material: Gr12 Other Aviliable Material: Gr1, Gr2, Gr3, Gr7,Gr12 Wall Thickness Range: 0.5-22mm Outer Diameter Range: 6-219mm Standard: ASTM B338; ASTM B861 Description: The titanium tube is of light weight, high strength and excellent mechanical performance. It is widely used in heat exchange equipment, such as tube heat exchanger, coil heat exchanger, coil heat exchanger, condenser, evaporator and

Corrosion Resisting Heat Exchanger Tube , Gr2 Gr9 Seamless Titanium Tube Description Item Name Heat Exchange Titanium Tubes ASTM B338 Gr1 Ge2 Gr3 Gr7 Gr9 Gr12 Gr16 Seamless Titanium Pipe For Industrial Grade Gr1,Gr2,Gr3,Gr5,Gr7,Gr9 Standard ASTM B337,ASTM B338 Specification 1) OD12.7×0.889×L 2) OD15.88×0.889×L 3) OD19.05×0.55×L 4) OD12.7×0.55×L 5) OD25.4×1.0×L Applications (1) Heat exchangers and condensers (2) Corrosive fluid transmission pipeline system (3) Titanium bicycle

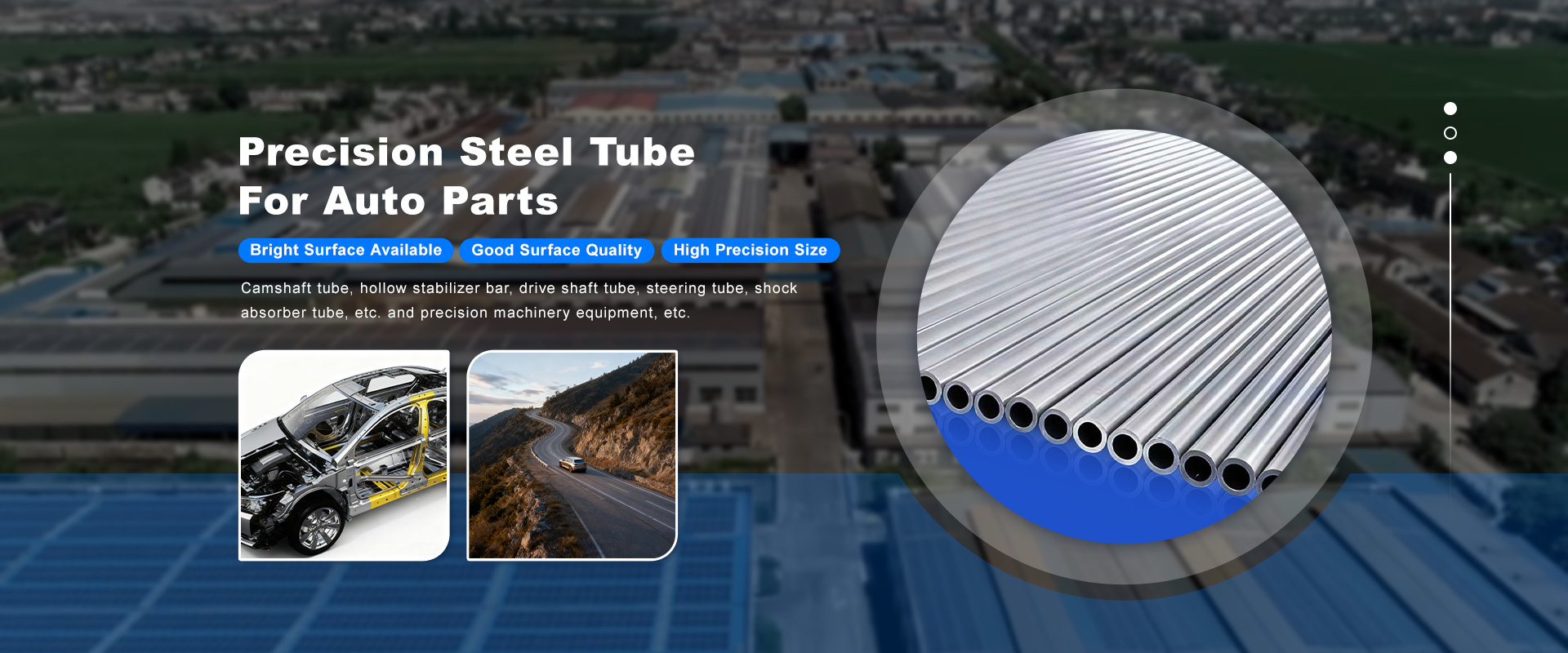

Automotive Steel Tube Seamless / Welding Steel Tube High Precision Cold-Drawing Material: ST37.4,ST52.4,E235,E355 Standard: EN10305 Application:High Precision Cold-Drawing/Cold-Rolling Steel Tube widely Used in Automotive Part Dimension Range: Outer Diameter:φ6-φ80 Wall Thickness: 0.5-10 Delivery Condition: +C Cold drawn / hard +LC Cold drawn / soft +SR Cold drawn and stress relieved +A Bright annealed +N Bright normalized Non-Destructive Test: Eddy current test Ultrasonic

DIN2391 E235 E355 Cold Drawn Precision Seamless Carbon Steel Tube Round Seasmless Steel Tube Description Product Name : EN 10305-1 E235 E355 +N cold drawn precision products seamless steel tube and pipe Shape : Round Outer Diameter: 5 - 250 mm Thickness: 2 - 30 mm Grade : 20# 45# 25Mn Q345 ID tolerance:H8 H9 Delivery Condition: BK/BKW/BKS/GBK/NBK Technique : Cold drawn+SR Technical specification : suitable for SK+RB/Honed or skived and telescopic hydraulic cylinder tube

-

1958

설립 해

-

700~1000 +

직원

-

76000000 +

연간 매출

-

2000+ +

고객 들 에게 봉사

신뢰 표지판, 신용 점검, RoSH 및 공급자 능력 평가 회사는 엄격한 품질 관리 시스템과 전문 테스트 실험실을 갖추고 있습니다.

사내 전문 디자인 팀과 첨단 기계 작업장. 귀하가 필요로 하는 제품을 개발하기 위해 협력할 수 있습니다.

첨단 자동 기계, 엄격한 공정 관리 시스템. 귀하의 요구 사항을 넘어 모든 전기 단자를 제조할 수 있습니다.

대용품 및 맞춤형 소형 패키지, FOB, CIF, DDU 및 DDP. 우리는 여러분의 모든 고민에 대해 최선의 해결책을 찾을 수 있도록 도와드리겠습니다.

석탄 광산의 메탄 배수 작업은 특히 안전과 신뢰성이 가장 중요한 가스 지하 환경에서 굴착 장비에 독특한 과제를 제기합니다.전통적인 굴착 파이프 는 종종 부식 가스의 합성 효과 와 싸우고 있다기계적 스트레스, 그리고 장비 고장의 지속적인 위협AISI 4130 합금강 드릴 파이프는 이러한 중요한 문제를 해결하면서 운영 효율성을 향상시키는 엔지니어링 솔루션으로 등장했습니다.. 메탄 배수용 용 용품에서 AISI 4130의 우수한 성능은 최적화된 화학 성분과 고급 열처리에서 비롯됩니다.크롬-몰리브덴 합금 조합은 탄수화물 및 메탄이 풍부한 대...

비철금속 채굴 작업은 산업 장비, 특히 경암 광석에서 귀중한 광물을 추출할 때 가장 까다로운 조건을 제시합니다. 연마성 광물 함량, 지속적인 기계적 스트레스, 부식성 처리 화학 물질의 조합은 기존 강철 파이프를 빠르게 저하시키는 마모 요인의 완벽한 조합을 만듭니다. 이러한 운영상의 과제는 구조적 무결성을 유지하면서 극한 조건을 견딜 수 있는 고급 재료 솔루션을 필요로 합니다. AISI 4130 합금강은 이러한 가혹한 응용 분야를 위한 엔지니어링 등급 솔루션으로 부상했습니다. 이 재료의 뛰어난 성능은 크롬과 몰리브덴을 특징으로 하는 ...

정확성과 내구성이 가장 중요한 시대에 산업 부문은 극한 조건에서도 뛰어난 성능을 제공하는 재료에 대한 요구가 계속되고 있습니다.AISI 4130 매듭 없는 철강 파이프는 최고의 선택으로 돋보인다, 높은 강도, 우수한 견고성, 그리고 뛰어난 피로 저항의 예외적인 조합을 제공합니다.이 크롬-몰리브덴 금속은 다양한 산업에서 중요한 응용을 위해 특별히 설계되었습니다.. AISI 4130의 고유 속성은 석유 및 가스 작업에 특히 가치가 있습니다. 신뢰할 수있는 껍질, 파이프,강압의 압력 및 부식성 환경에 견딜 수 있는 뚫림 파이프 부품마찬가...

프리미엄 오일 & 가스 드릴링 파이프 (4140 등급)1. 극한 조건에 대한 예외적인 기계적 강도팽창 강도: ≥950 MPa (극도로 높은 압력 하에서 폭발 및 붕괴에 대한 우수한 저항, 깊은 / 복잡한 우물에 이상적입니다.)내력 강도: ≥850 MPa (중량 부하에서도 구조적 무결성을 유지하여 장기적인 굴착 작업에서도 변형을 방지합니다.) - 네 2. 더 나은 마모 저항을 위해 최적화 된 경화 (28?? 33 HRC)단단한 표면 (죽여 & 완화) 은 굴착 절단 및 형성 마찰에 대한 우수한 경직 저항을 제공하여 서비스 수명을 연장합...

AISI 4130 합금강 이음매 없는 유정 파이프, 케이싱 튜브용 강관 설명 중요한 석유 및 가스 작업에서 탁월한 성능을 발휘하도록 설계된 AISI 4130 합금강 이음매 없는 파이프는 케이싱 튜브 및 다운홀 구성 요소에 대한 최적의 솔루션입니다. 이 크롬-몰리브덴(크로몰리) 합금은 가혹한 유정 환경에 필수적인 강도, 인성 및 환경 저항성의 우수한 균형을 제공합니다. 비할 데 없는 강도 및 내구성: AISI 4130 크로몰리강의 고유한 특성은 표준 탄소강에 비해 훨씬 높은 인장 강도와 항복 강도를 제공합니다. 이는 극한의 다운홀 압...

34CrMo4 4130 오일 드릴링 파이프 - 드릴 로드 튜빙용 중요 적용 분야 설명 이 34CrMo4/4130 크롬 몰리 합금 드릴링 파이프는 실패가 용납되지 않는 중요한 드릴링 분야를 위해 설계된 고성능 이음매 없는 튜빙을 나타냅니다. 엄격한 국제 표준에 따라 제조된 이 파이프는 최소 110,000psi 항복 강도, 뛰어난 충격 인성, 가장 까다로운 지하 조건에 대한 우수한 피로 저항성을 포함한 뛰어난 기계적 특성을 제공합니다. 크롬-몰리브덴강의 최적화된 화학 조성은 응력 부식 균열 및 수소 취성에 대한 향상된 저항성을 특징으로 ...

EN 10305-1 E235 E355 +N 냉각 압연 이음새가 없는 강철 관 냉각 압연 정밀도 관 묘사 제품 이름: EN 10305-1 E235 E355 +N 냉각 압연 정밀도 제품 이음새가 없는 강철 관 및 관 모양: 둥근 외부 직경: 5개 - 250 mm 간격: 2개 - 30 mm 급료: 20# 45# 25Mn Q345 ID 포용력: H8 H9 납품 상태: BK/BKW/BKS/GBK/NBK 기술: 냉각 압연 +SR 기술 명세: SK+RB/Honed 또는 찢다 망원경 액압 실린더 관을 위해 적당한 지상 질: 입히기 후에 좋은 품질 ...

Customized Length Welded Steel Tube with Beveled Ends and Galvanized Surface for Various Applications

ASTM A519 Alloy Steel Oil Well Drill Pipe, Seamless Chromoly Tubing for Nonferrous Metal Mining Projects

Outer Diameter 90MM 4130 Oil Drilling Pipe Alloy Steel Pipe for Casing Pipe

ASTM A513 A519 Drill Rod Oil Drilling Pipe 42CrMo4 Steel Outer Tube with Excellent microstructure

A519 4130 오일 웰 파이프, 까다로운 유정 환경을 위한 이음매 없는 합금강 파이프

기름 - 복각 액체를 운반하는 냉각 압연 이음새가 없는 강철 관 ID 포용력 H8 H9

고정확도 정밀도 이음새가 없는 강철 관, 똑바른 솔기 구렁 금속 관

콘덴서 냉각 압연 이음새가 없는 관 검정에 의하여 기름을 바르는 반대로 - 부식성 처리

무료 인용을 받으세요

언제나 여러분을 도울 준비가 되어 있습니다. 저희에게 연락하는 방법은 여러 가지가 있습니다. 간단한 메모를 남기시거나, 전화하시거나, 이메일을 보내실 수 있습니다. 가장 편한 방법을 선택하세요.

- 86-512-58715276

- export@hongbao.com

- DAXIN 도시, 장자강 시, 장쑤 성 P.R.CHINA